Errata

NFPA 25

Standard for the Inspection, Testing, and Maintenance of

Water-Based Fire Protection Systems

2017 Edition

Reference: Various

Errata No: 25-17-1

The Technical Committee on Inspection, Testing, and Maintenance of Water-Based Protection

Systems notes the following errors in the 2017 edition of NFPA 25, Standard for the Inspection,

Testing, and Maintenance of Water-Based Fire Protection Systems.

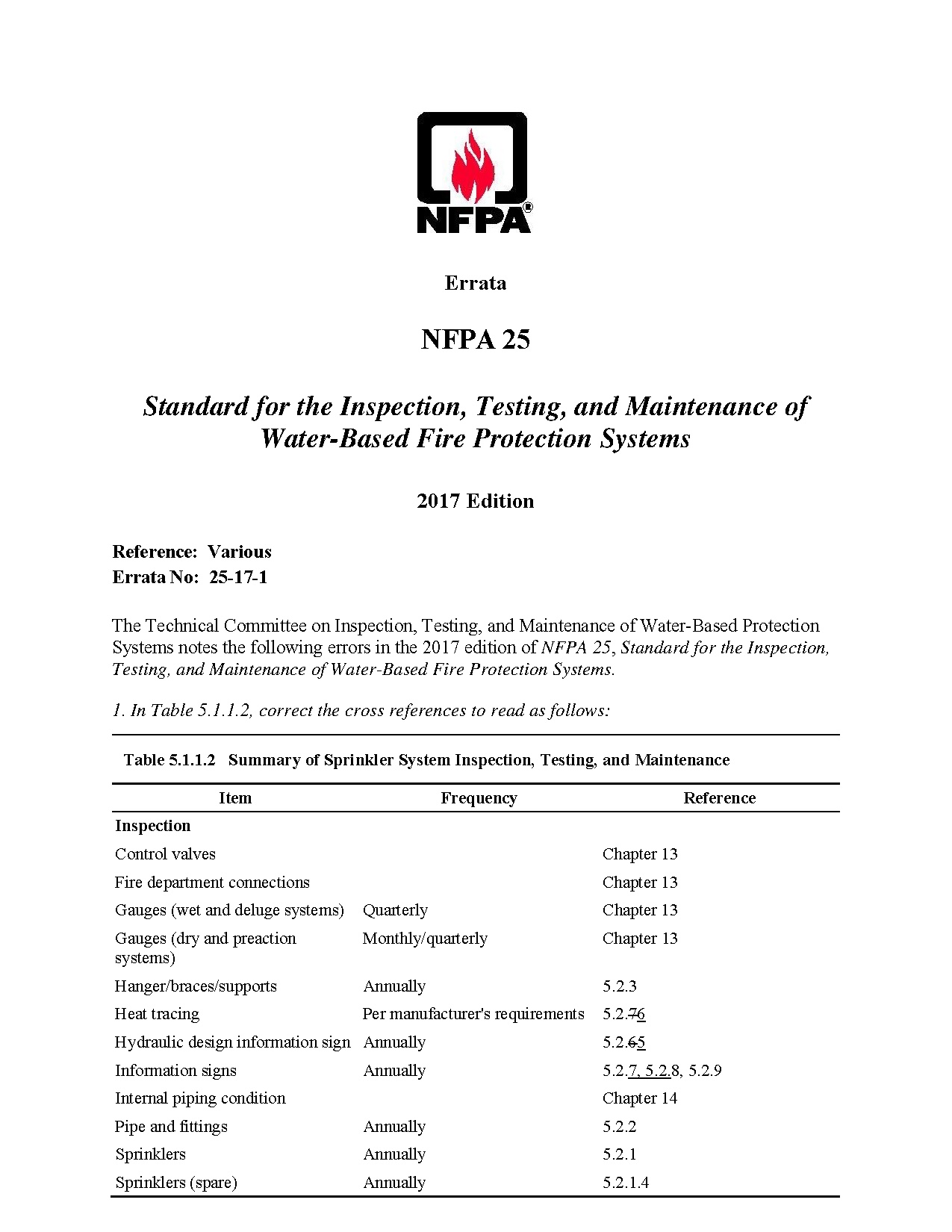

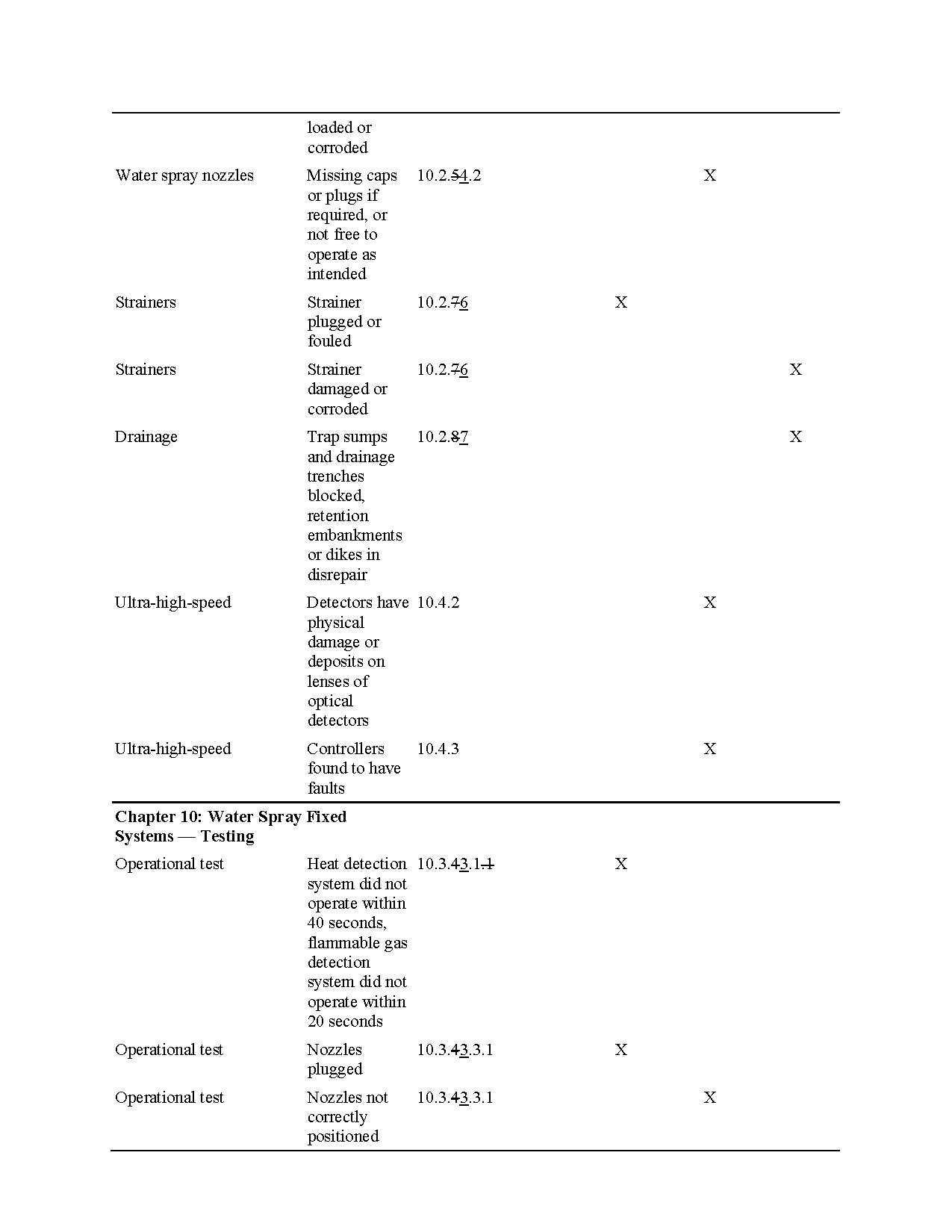

1. In Table 5.1.1.2, correct the cross references to read as follows:

Table 5.1.1.2 Summary of Sprinkler System Inspection, Testing, and Maintenance

Item

Frequency

Reference

Inspection

Control valves

Chapter 13

Fire department connections

Chapter 13

Gauges (wet and deluge systems)

Quarterly

Chapter 13

Gauges (dry and preaction

systems)

Monthly/quarterly

Chapter 13

Hanger/braces/supports

Annually

5.2.3

Heat tracing

Per manufacturer's requirements

5.2.76

Hydraulic design information sign Annually

5.2.65

Information signs

5.2.7, 5.2.8, 5.2.9

Annually

Internal piping condition

Chapter 14

Pipe and fittings

Annually

5.2.2

Sprinklers

Annually

5.2.1

Sprinklers (spare)

Annually

5.2.1.4

Supervisory signal devices (except Quarterly

valve supervisory switches)

5.2.54

System valves

Chapter 13

Valve supervisory signal devices

Quarterly

5.2.54

Waterflow alarm devices

Quarterly

5.2.54

Annually

5.3.43

Test

Antifreeze solution

Control valves

Gauges

Chapter 13

5 years

Main drain

Chapter 13

Chapter 13

Sprinklers

At 50 years and every 10 years

thereafter

5.3.1.1.1, 5.3.1.1.1.1, 5.3.1.1.1.2

Sprinklers

At 75 years and every 5 years

thereafter

5.3.1.1.1.5

Sprinklers (dry)

10 years and every 10 years

thereafter

5.3.1.1.1.6

Sprinklers (extra high or greater

temperature solder type)

5 years

5.3.1.1.1.4

Sprinklers (fast-response)

At 20 years and every 10 years

thereafter

5.3.1.1.1.3

Sprinklers (harsh environments)

5 years

5.3.1.1.2

Supervisory signal devices (except

valve supervisory switches)

Chapter 13

System valves

Chapter 13

Valve supervisory signal devices

Chapter 13

Waterflow alarm devices

(Mechanical)

Quarterly

5.3.32.1

Waterflow alarm devices (vane

and pressure switch type)

Semiannually

5.3.32.2

Maintenance

Low-point drains (dry pipe and

preaction systems)

Chapter 13

Annually

Sprinklers and automatic spray

nozzles protecting commercial

cooking equipment and ventilation

systems

5.4.1.7

Valves (all types)

Chapter 13

Investigation

Obstruction

Chapter 14

2. In Table 6.1.1.2, correct the cross references to read as follows:

Table 6.1.1.2 Summary of Standpipe and Hose Systems Inspection, Testing, and Maintenance

Item

Frequency

Reference

Inspection

Cabinet

Annually

Control valves

6.2.18

Chapter 13

Gauges

Weekly/quarterly

Chapter 13

Hose

Annually

NFPA 19626.2.5

Hose connection

Annually

6.2.13

Hose nozzle

Annually and after each use

NFPA 19626.2.6

Hose storage device

Annually

6.2.17

Hydraulic design information sign Annually

6.2.32

Hose valves

Chapter 13

Hose connection

Annually

6.2.1

Piping

Annually

6.2.14

Pressure-regulating devices

Chapter 13

Test

Flow test

5 years

6.3.1

Hose

5 years/3 years

NFPA 1962

Hose connections

Annually

6.2.1

Hose valves

Hydrostatic test

Chapter 13

5 years

6.3.2

Main drain test

Chapter 13

Pressure control valve

Chapter 13

Pressure-reducing valve

Chapter 13

Supervisory signal devices (except

valve supervisory switches)

Chapter 13

Valve status test

Chapter 13

Valve supervisory devices

Chapter 13

Waterflow alarm devices

Chapter 13

Maintenance

Hose connections

Annually

Hose valves

Valves (all types)

Table 6.1.2

Chapter 13

Annually/as needed

Chapter 13

3. Correct the cross references in 8.3.3.6.3.3 and 8.3.3.6.3.4 to read as follows:

8.3.3.6.3.3 If the test results are not consistent with the previous annual test, the test shall be

repeated using the test arrangement described in 8.3.3.6.3.1.

8.3.3.6.3.4 If testing in accordance with 8.3.3.6.3.1 is not possible, a flowmeter calibration

shall be performed and the test shall be repeated.

4. In Table 9.1.1.2, correct the cross references to read as follows:

Table 9.1.1.2 Summary of Water Storage Tank Inspection, Testing, and Maintenance

Item

Frequency

Reference

Inspection

Air pressure—tanks that have their air pressure

source supervised

Quarterly

9.2.2.1

Air pressure—tanks without their air pressure

source supervised

Monthly

9.2.2.2

Catwalks and ladders

Quarterly

9.2.54.1

Check valves

Chapter 13

Control valves

Chapter 13

Expansion joints

Annually

9.2.54.3

Heating system — tanks with supervised low

temperature alarms connected to constantly

attended location

Weekly*

9.2.32.1

Heating system — tanks without supervised low

temperature alarms connected to constantly

attended location

Daily*

9.2.32.2

Hoops and grillage

Annually

9.2.54.4

Interior — all other tanks

5 years

9.2.65.1.2

Interior — steel tanks without corrosion

protection

3 years

9.2.65.1.1

Painted/coated surfaces

Annua

...

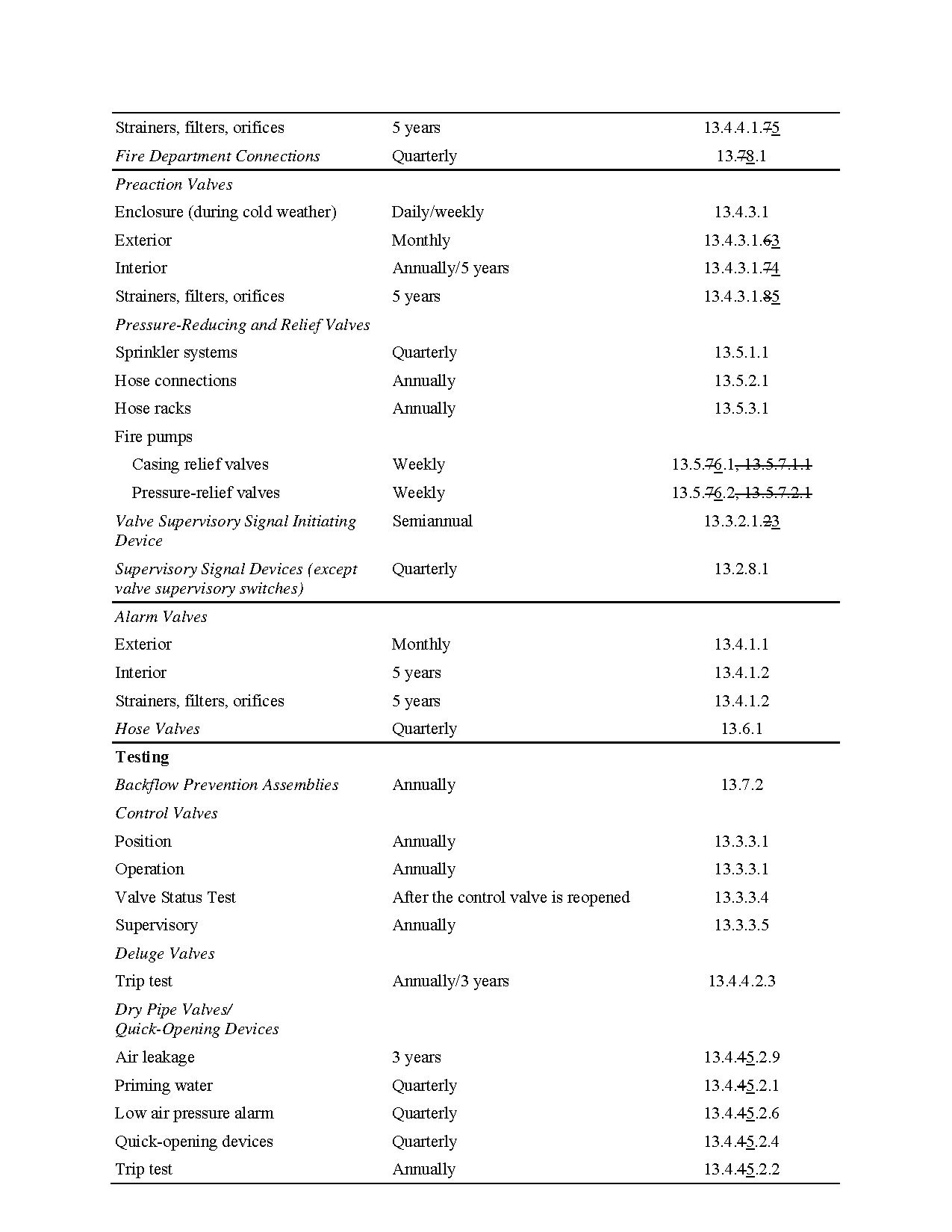

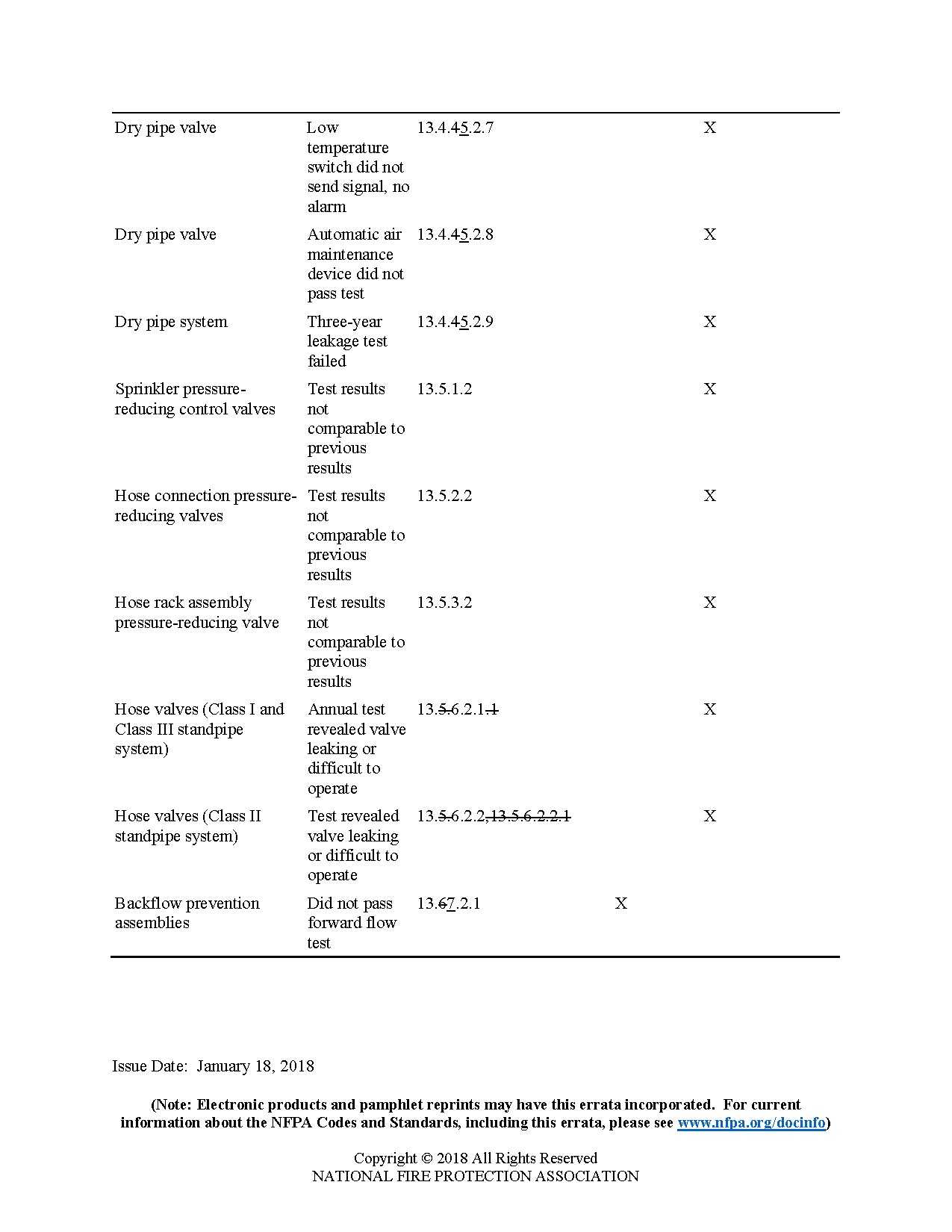

--------------------------------------

...temperature

13.4.3.1.1,

13.4.4.1.1

X

Valve enclosure

Low

temperature

alarms (if

installed) are

physically

damaged

13.4.3.1.1,

13.4.4.1.1

X

13.4.3.1.63, 13.4.4.1.3

X

Preaction valve and deluge External

valve

physical

damage, trim

valves not in

X

X

X

X

appropriate

open or closed

position, valve

seat leaking

Preaction valve and deluge Electrical

valve

components

not in service

13.4.3.1.63, 13.4.4.1.3

X

Dry pipe valve/quickopening device

13.4.4.1.45.1.3

External

physical

damage, trim

valves not in

appropriate

open or closed

position,

intermediate

chamber

leaking

Sprinkler pressurereducing control valves

Not in open

position

13.5.1.1

Sprinkler pressurereducing control valves

Not

maintaining

downstream

pressures in

accordance

with design

criteria

13.5.1.1

X

Sprinkler pressurereducing control valves

Leaking, valve 13.5.1.1

damaged,

hand wheel

missing or

broken

X

13.5.2.1

Hose connection pressure- Hand wheel

reducing valves

broken or

missing, hose

threads

damaged,

leaking,

reducer

missing

X

X

X

Hose connection pressure- Cap missing

reducing valves

13.5.2.1

X

Hose rack assembly

pressure-reducing valve

Hand wheel

broken or

missing,

leaking

13.5.3.1

X

Hose valves

13.56.6.1

Leaking,

visible

obstructions,

caps, hose

threads, valve

X

handle, cap

gasket, no

restricting

device,

damaged, or in

poor condition

Hose valves

Hose threads 13.56.6.1

not compatible

Backflow prevention

assemblies

13.67.1.21

Reducedpressure

assemblies,

differentialsensing valve

relief port

continuously

discharging

Fire department

connection

Not

accessible,

damaged

couplings, or

clapper not

operating

properly or

missing

Fire department

connection

Couplings and 13.78.1

swivels

damaged, do

not rotate

smoothly,

check valve

leaking,

automatic

drain not

operating

properly or

missing

Fire department

connection

Missing

identification

sign

13.78.1

X

X

X

X

13.78.1

X

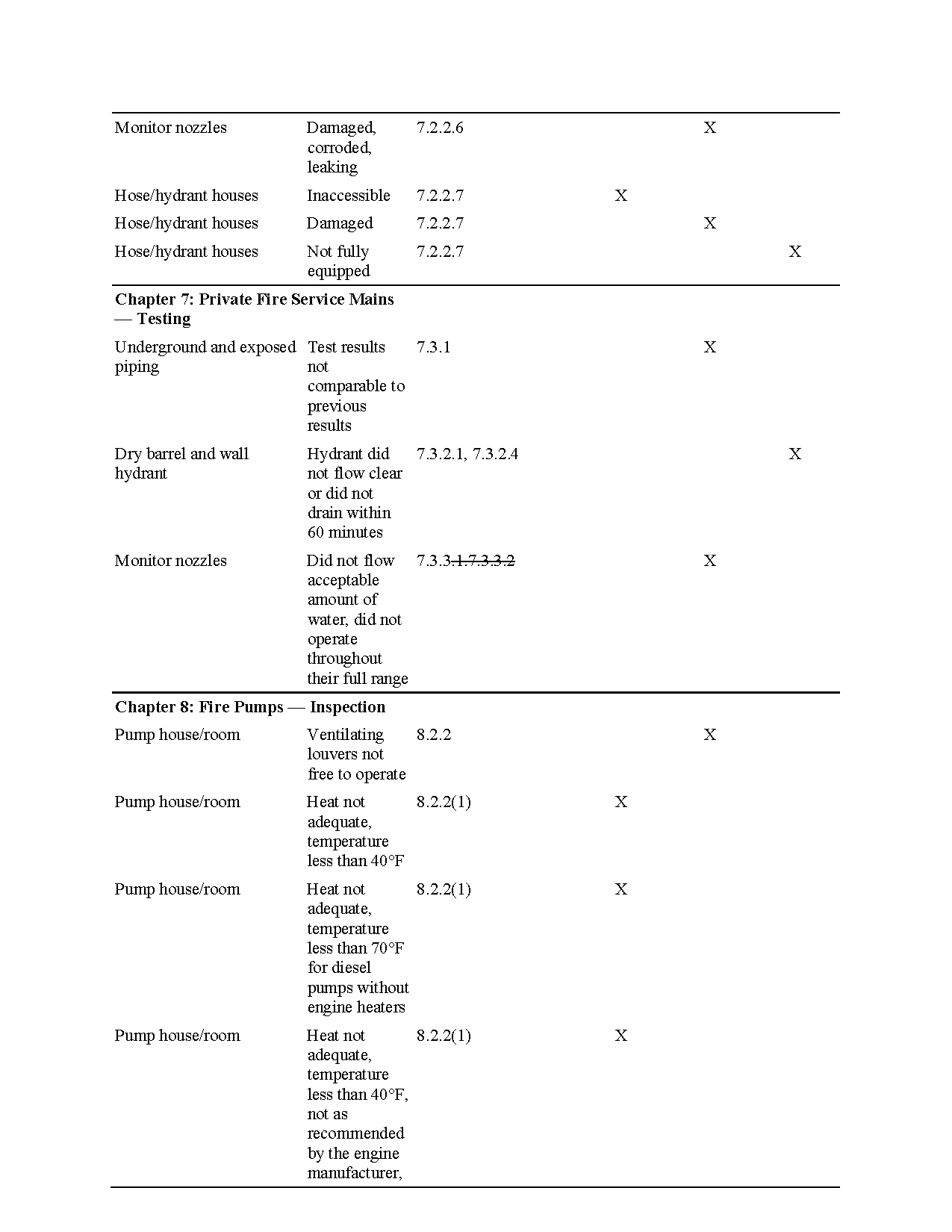

Chapter 13: Valves, Valve Components,

and Trim — Testing

Main drain

More than

10% drop in

full flow

pressure

13.2.5.23

X

Alarm devices

Water motor

and gong not

functioning

13.2.6.1

X

Alarm devices

Pressure

switch or

13.2.6.2

X

vane-type

switch not

functioning,

no alarm

Gauges

Not replaced 13.2.7.2,

or calibrated 13.2.7.3

in 5 years, not

accurate

within 3% of

scale

Control valve

13.3.3.1

Valve not

operating

through its full

range

Control valve

No spring or 13.3.3.2

torsion felt in

rod when

opening post

indicator valve

Supervisory switches

13.3.3.5.2

No signal

from two

revolutions of

hand wheel

from normal

position or

when stem has

moved onefifth of

distance from

normal

position,

signal restored

in position

other than

normal

X

Preaction valve

Priming water 13.4.3.2.1

level not

correct

X

Preaction valve

13.4.4.23.2.2

Pressure

reading at

hydraulically

most remote

nozzle and/or

at valve not

comparable to

original design

values

X

Preaction valve

Three-year

leakage test

failed

X

13.4.3.2.65

X

X

X

13.4.3.24.2.3

Deluge valve

Annual full

flow trip test

revealed

plugged

nozzles,

manual

actuation

devices did

not operate

properly

Deluge valve

13.4.3.24.2.3

Pressure

reading at

hydraulically

most remote

nozzle and/or

at valve not

compatible

with original

design values

X

Preaction valve

13.4.3.2.1210

Low air

pressure

switch did not

send signal, no

alarm

X

13.4.3.2.11,

Preaction and deluge valve Low

13.4.4.2.14

temperature

switch did not

send signal, no

alarm

X

X

X

Preaction valve

Automatic air 13.4.3.2.1412

maintenance

device did not

pass test

Dry pipe valve

Priming water 13.4.45.2.1

level not

correct

X

Dry pipe valve

13.4.45.2.2.2

Test results

not

comparable

with previous

results

X

Quick-opening device

Quick-opening 13.4.45.2.4

device did not

pass test

X

Dry pipe valve

Low air

13.4.45.2.6

pressure

switch did not

send signal, no

alarm

X

Dry pipe valve

Low

13.4.45.2.7

temperature

switch did not

send signal, no

alarm

X

Dry pipe valve

Automatic air 13.4.45.2.8

maintenance

device did not

pass test

X

Dry pipe system

Three-year

leakage test

failed

X

Sprinkler pressurereducing control valves

Test results

13.5.1.2

not

comparable to

previous

results

X

Hose connection pressure- Test results

13.5.2.2

reducing valves

not

comparable to

previous

results

X

Hose rack assembly

pressure-reducing valve

Test results

13.5.3.2

not

comparable to

previous

results

X

Hose valves (Class I and

Class III standpipe

system)

13.5.6.2.1.1

Annual test

revealed valve

leaking or

difficult to

operate

X

Hose valves (Class II

standpipe system)

Test revealed

valve leaking

or difficult to

operate

13.5.6.2.2,13.5.6.2.2.1

Backflow prevention

assemblies

Did not pass

forward flow

test

13.67.2.1

13.4.45.2.9

X

X

Issue Date: January 18, 2018

(Note: Electronic products and pamphlet reprints may have this errata incorporated. For current

information about the NFPA Codes and Standards, including this errata, please see www.nfpa.org/docinfo)

Copyright © 2018 All Rights Reserved

NATIONAL FIRE PROTECTION ASSOCIATION