Communications guidance

Printing processes explained

WRAP’s vision is a world without waste,

where resources are used sustainably.

We work with businesses and individuals

to help them reap the benefits of reducing

waste, develop sustainable products and

use resources in an efficient way.

Find out more at www.wrap.org.uk

Written by: Stefan Wilczak, Get it Sorted Ltd on behalf of WRAP

Document reference: [e.g. WRAP, 2006, Report Name (WRAP Project TYR009-19. Report prepared by…..Banbury, WRAP]

WRAP believes the content of this report to be correct as at the date of writing. However, factors such as prices, levels of recycled content and regulatory requirements

are subject to change and users of the report should check with their suppliers to confirm the current situation. In addition, care should be taken in using any of the cost

information provided as it is based upon numerous project-specific assumptions (such as scale, location, tender context, etc.).

The report does not claim to be exhaustive, nor does it claim to cover all relevant products and specifications available on the market. While steps have been taken to

ensure accuracy, WRAP cannot accept responsibility or be held liable to any person for any loss or damage arising out of or in connection with this information being

inaccurate, incomplete or misleading. It is the responsibility of the potential user of a material or product to consult with the supplier or manufacturer and ascertain

whether a particular product will satisfy their specific requirements. The listing or featuring of a particular product or company does not constitute an endorsement by

WRAP and WRAP cannot guarantee the performance of individual products or materials. This material is copyrighted. It may be reproduced free of charge subject to the

material being accurate and not used in a misleading context. The source of the material must be identified and the copyright status acknowledged. This material must

not be used to endorse or used to suggest WRAP’s endorsement of a commercial product or service. For more detail, please refer to WRAP’s Terms &amp Conditions on its

web site: www.wrap.org.uk

Contents

1.0

2.0

3.0

4.0

Introduction ................................................................................................................................. 4

Paper and Print Finishing ............................................................................................................ 4

2.1

Recycled Content ..................................................................................................................... 4

2.2

Paper weights and printability ................................................................................................... 4

2.3

Paper Coatings ........................................................................................................................ 5

2.4

Folding, Finishing and Perforating ............................................................................................. 5

2.5

Die Cutting and Laminating ...................................................................................................... 6

2.6

Going to Print .......................................................................................................................... 6

Print Processes ............................................................................................................................ 6

3.1

Types of Process ...................................................................................................................... 6

3.2

Litho Printing ........................................................................................................................... 7

3.3

Screenprint.............................................................................................................................. 8

3.4

Digital Printing ......................................................................................................................... 8

3.5

Printing Processes – Pros and Cons ........................................................................................... 9

Additional Support ....................................................................................................................... 9

Print guidance for local authorities

3

1.0

Introduction

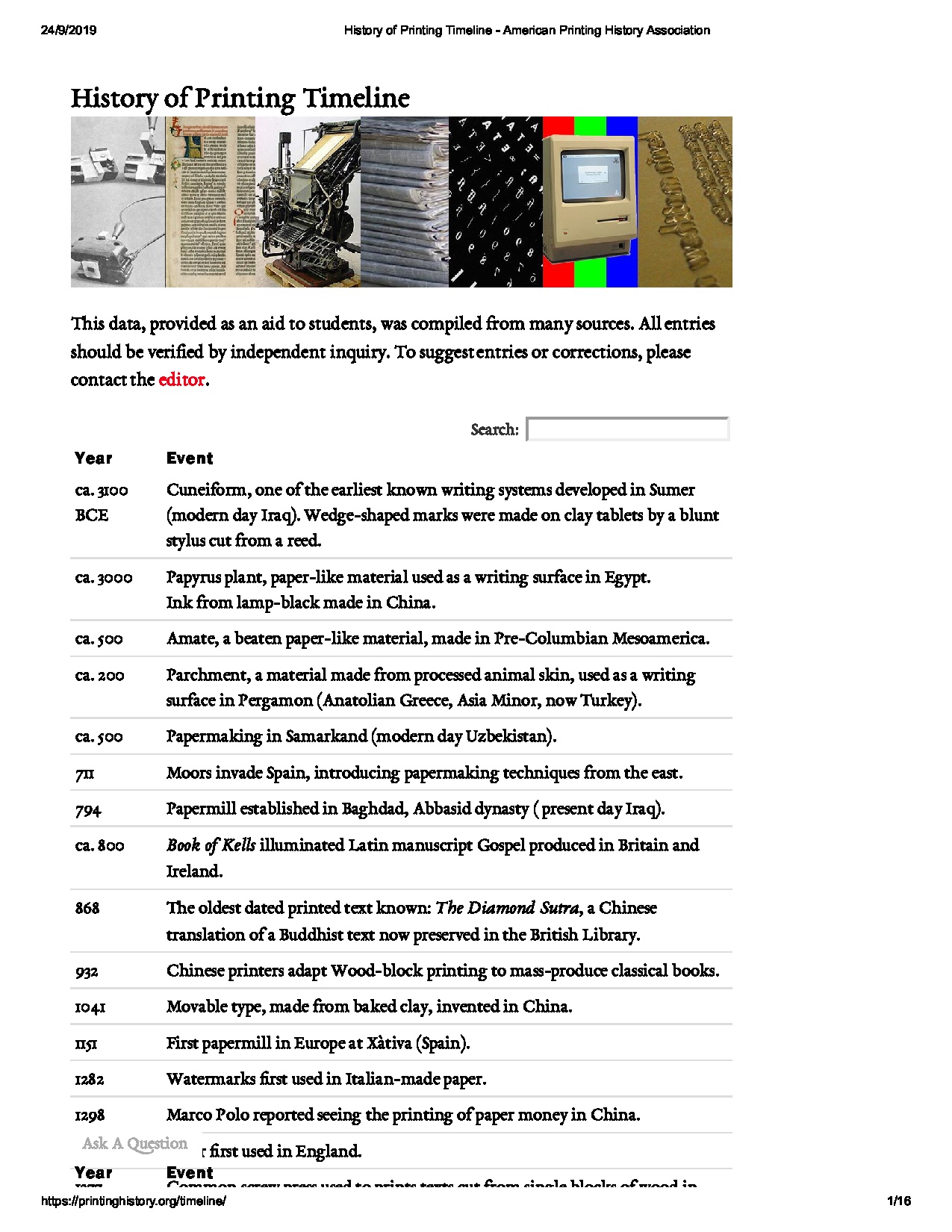

The purpose of this guide is to raise awareness and understanding of the print processes in common use and

how they work. More specifically it deals with litho printing on paper and card for leaflets and posters and

touches on screen-print and digital printing where print numbers are small or different materials needs to be

printed. Section 2 provides a basic insight into paper and print finishing, section 3 an explanation of print

processes.

2.0

Paper and Print Finishing

A very important part of the design process is ing the paper on which you will be printing. It is essential

that consideration is given to the paper type, its weight and suitability for what you are trying to achieve.

There are a vast number of types of paper available at differing recycled contents, weights, coating and whether

to use rolls or sheets amongst other factors. Finishing is the term applied to any process after the paper is

printed. The main issues involved in paper ion and finishing are summarised below.

2.1

Recycled Content

Recycling is necessary to provide an native to landfilling of paper waste. The procurement of recycled

content paper is part of the Government’s sustainability policy and is part of many private companies’ Corporate

Social Responsibility (CSR) agendas. Many local authorities have integrated ‘buy recycled’ procurement policies.

WRAP recommends you stipulate a minimum of 50% recycled content, where recycled content includes pre and

post consumer waste but excludes mill broke. Virgin pulp should come from a sustainable source.

Use a recycled paper, which looks recycled only if you want that effect – otherwise go for a recycled paper with a

bright white coated finish as it shows the colours better. Settle on one type of paper for all leaflets as it will show

your colours more consistently. Discuss this with your designer or printer, as they will have experience of the

options.

Several procurement guides are also available through WRAP these include:

2.2

Specifying recycled content in office paper and publications

Specifying recycled content in business process services for your organisation and

Specifying recycled content in tissue paper in your organisation.

Paper weights and printability

Paper and card is made in many different weights, which are specified as “grams per square metre of paper”

noted as gsm, g/m2 or gm2. Specific types of documents will require different weights. For example:

Lightweight for flyers and leaflets say 130gsm although 170gsm will give a quality feel with little

additional cost and not suffer from show through

Card for leaflets with a return postcard say 230 gsm (a minimum requirement from the Post Office)

and

Laminated on both sides for a recycling calendar or bin hanger, say 350–400gsm that may be

delivered via the recycling boxes and may get wet (note only use lamination when necessary as the

paper cannot then be recycled).

‘Show through’ is the ability of the paper to stop show-through of text or images

from the other side – this is dependent on the amount of filler in the paper and

its weight amongst other factors. It also depends on what is called the strikethrough of the ink (how far the ink is absorbed into the paper) or hold-out (the

paper’s capacity to keep ink on the surface). So even though a paper may be

thicker or heavier it may show through more if it is more absorbent. A minimum

weight for leaflets should be considered as 130 gsm, which will ensure only a

nominal amount of show-through of print from the other side.

To keep a consistent

look in a project or

campaign the same

paper should be

used throughout if

possible

Print guidance for local authorities

4

The less absorbent a paper the better it will reproduce half tones and colours as the ink tends to sit on the

surface of the paper much more. The type of paper and the finish will affect the way the colours reproduce.

When printing on heavier weights of paper such as 200 gsm and above it is preferable to crease the leaflet where

it is to be folded prior to folding. Heavier papers tend to crack on the fold and the white of the paper will show

through the colour of the print giving and untidy edge. This does not happen on lighter papers, folding is

carried out without creasing. Creasing is normally a separate additional process, which adds to the overall cost.

2.3

Paper Coatings

The finish on paper can be specified – usually gloss, silk/eggshell and matt. This is d in the manufacturing

process. After the paper is made and coated it is passed through rollers called calendars which can either impart

a texture or make the paper smooth and glossy. Glossy paper is rolled at higher pressures t

...

...ix different colours to simulate more accurately the colour spectrum but this one in particular is used for high

quality print work.

If there are colour photographs to reproduce a four plate press will be required. For two colour work a two plate

press can be used. Two colour printing can be very effective and will be slightly lower cost as there are fewer

plates to make and a two unit press can be used.

Colours will be reproduced reasonably accurately but there may be some inconsistency from one piece of work to

another. If an accurate colour reproduction is required, for example where there is a corporate colour that needs

to be reproduced exactly, it will be necessary to print using an ink specially mixed to the req